![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : zhimachine@foxmail.com

Tel : +86 18221614363

processing capacity:100-10000/H

Application scope:Cookie & biscuit & cake

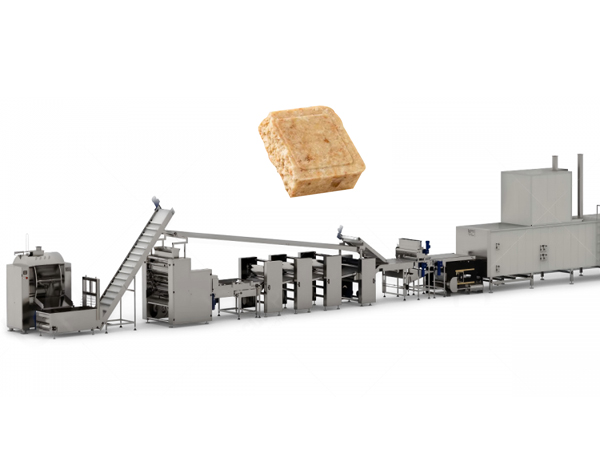

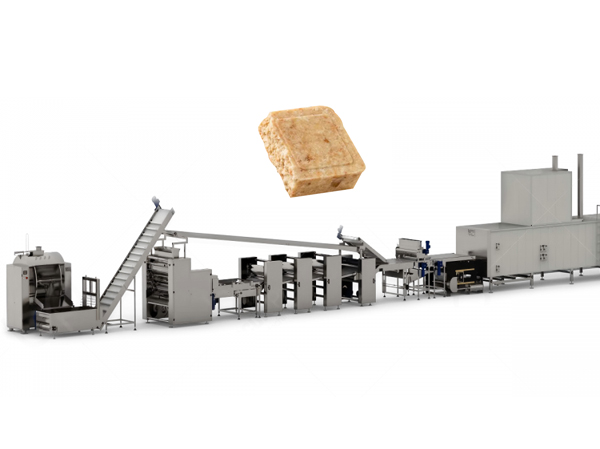

Product introduction: Introduction to the fully automatic ship biscuit production line: Equipment composition, including flour mixer, biscuit forming machine, tunnel oven, cooling conveyor belt, biscuit grinder, compressed biscuit forming machine, vacuum packaging machine, etc

Automatic ship biscuit production line introduction

Equipment Composition

Flour Mixer: Mix the flour and other raw materials evenly to form the base dough.

Biscuit molding machine: presses the dough and cuts it into set shapes to prepare for subsequent baking.

Tunnel Oven: Adopting electric, gas or diesel heating to ensure even baking of Biscuits.

Cooling conveyor: cools the baked Biscuits to stabilize their texture.

Biscuit Grinding Machine: Grinds the Biscuits after baking and cooling into small pieces to prepare for compression.

Compression Biscuit Molding Machine: Compresses the ground Biscuit powder by pneumatic and hydraulic system.

Vacuum Packaging Machine: Vacuum packaging the compressed Biscuits to extend the shelf life and maintain the taste.

Working Principle of cookie production line

Dough Preparation: Flour Mixer mixes the raw materials into a homogeneous dough.

Forming: Biscuit molding machine presses the dough into thin sheet and cuts it into shape.

Baking: The molded Biscuits enter the tunnel oven and finish baking under suitable temperature control.

Cooling: After baking, the Biscuits are cooled down on a cooling conveyor to stabilize the texture.

Grinding: The Biscuit grinder grinds the cooled Biscuits into small pieces.

Compression molding: The compression Biscuit molding machine uses pneumatic and hydraulic systems to compress the Biscuit powder into shape.

Packing: Vacuum packaging machine packs the compressed Biscuits.

Technical features and advantages

High automation: high degree of automation of the whole line, reducing manual intervention, improving production efficiency and product quality stability.

Diversified products: It can produce many types of cookies to meet different consumer demands.

Energy saving and high efficiency: the oven adopts energy-saving technology to reduce energy consumption.

Easy to operate: Equipped with user-friendly control panel, easy to operate.

Hygienic design: made of 304 stainless steel, easy to clean and ensure food safety.

Scope of application

Suitable for food factories, schools, pastry stores, etc. It can produce compressed cookies, diet cookies, roughage cookies and many other products.

After-sales support

We provide a full range of after-sales service, including installation and commissioning, operation training, maintenance, etc., to ensure the stable operation of the production line.

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer