![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : zhimachine@foxmail.com

Tel : +86 18221614363

processing capacity:20-1200KG/H

Application scope:Chewing gum production line can produce ball chewing gum square chewing gum shaped chewing gum filled gum and so on

Product introduction: Automatic chewing gum production line can produce round, spherical, square, rectangular, piece shape and other chewing gum, chewing gum making machine is reliable flexible and simple operation high degree of automation.

Automatic chewing gum production line can produce round, spherical, square, rectangular, piece shape and other chewing gum, chewing gum making machine is reliable flexible and simple operation high degree of automation.

1.Automatic chewing gum production line

2.Central-filling Ball chewing gum production line

3.Automatic square chewing Gum Production Line

4.Irregular shape Chewing Gum Production Line

5.Automatic Xylitol chewing gum production line

6.Chewing Gum types (candy shapes) and applications

7.Chewing gum chewability

8.Chewing Gum making Machine Working Principle

9.Installation of the Chewing gum making machines

10.Chewing gum production line for sales and price

1.Automatic chewing gum production line

Automatic chewing gum production line

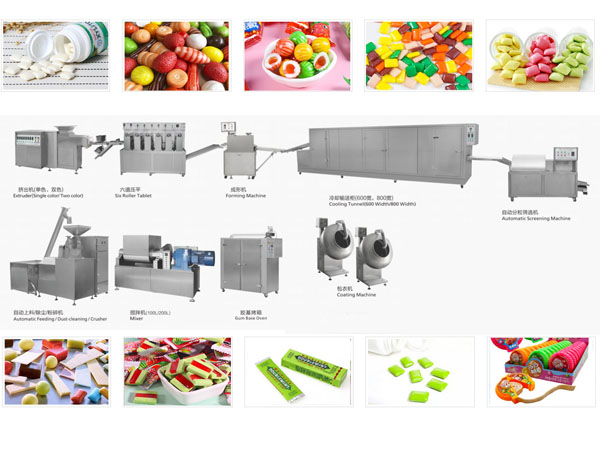

This fully-automatic chewing gum production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. It can produce different shapes of chewing gum, such as Circular shape,Ball shape,square, rectangular, tablet etc. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing chewing gum candy.

Process flow chart of chewing gum Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main Technical Parameters For Production Line

Capacity:500-600(kg/h)

Adjustable range for candy:Bean Shape :6mm-22mm;Rectangle Shape:6mm-30mm,Circular shape:6mm-22mm

Dimension:22000x1800x1750mm

Gross power:75 kw

Power supply:380V/50HZ 200V-240V/60HZ

Gross weight:11000kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/ Crushing Machine:Power:17kw,Dimension:3500x1300x2200mm,Weight:400kg

Gum Base oven:Power:18kw,Dimension:1600x600x1700mm,Weight:300kg

Mixer-100L:Power: 20 kw,Dimension:2300x860x1550mm,Weight:1500kg

Mixer-200L:Power: 24 kw,Dimension:2650x1000x1650mm,Weight:2000kg

Extruder -One Color:Power: 15kw,Dimension:2500x900x1500mm,Weight:1000kg

Extruder -Two Color:Power:22 kw,Dimension:2600x1150x1500mm,Weight:2200kg

Six Roller Tablet:Power:5 kw,Dimension:5100x950x1880mm,Weight:2000kg

Forming Machine:Power:2.2 kw,Dimension:1800x780x1650mm,Weight:800kg

Cooling Tunnel-600 Width:Power:20 kw,Dimension:8850x1900x1850mm,Weight:2500kg

Cooling Tunnel-800 Width:Power:22 kw,Dimension:8850x2100x1850mm,Weight:2700kg

Automatic Screening Machine:Power:3 kw,Dimension:2200x1000x1400mm,Weight:350kg

Coating Machine:Power:2 kw,Dimension:1050x1050x1600mm,Weight:350kg

2.Central-filling Ball chewing gum production line

Central-filling Ball chewing gum production line

Central-filling Ball chewing gum production line is composed by mixer, extruder, cooling tunnel/3 layers conveyor, forming machine (6 sets), coating machine, jelly filled forming machine and gum base oven. It can be produced hollow, powder filling or jelly filling candy in the shapes of balls, strawberry, oval, column, and so on.

Process flow chart of Round Bubble Gum Production Line

mixer-extruder-cooling tunnel/3 layers conveyor-forming machine-coating machine-jelly filled forming machine-gum base oven

Main Technical Parameters For Production Line

Capacity:400-650(kg/h)

Diameter of candy:10-25mm

Dimension:15000x4000x1500mm

Gross power:82kw

Power supply:380V

Gross weight:8850kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/ Crushing Machine:Power:17kw,Dimension:3500x1300x2200mm,Weight:400kg

Gum Base oven:Power:18kw,Dimension:1600x600x1700mm,Weight:300kg

Mixer-100L:Power:20kw,Dimension:2300x860x1550mm,Weight:1500kg

Mixer-200L:Power:24kw,Dimension:2650x1000x1650mm,Weight:2000kg

Extruder-One Color:Power:15kw,Dimension:2500x900x1500mm,Weight:1000kg

Extruder-Two Color:Power:22kw,Dimension:2600x1150x1500mm,Weight:2200kg

Jelly Pump:Power:3kw,Dimension:1600x550x1650mm,Weight:300kg

Cooling Tunnel-600:Power:20kw,Dimension:8850x1900x1850mm,Weight:2500kg

Cooling Tunnel-800:Power:22kw,Dimension:8850x2100x1850mm,Weight:2700kg

Three layers Convryor:Power:2.3kw,Dimension:10500x900x1450mm,Weight:300kg

Forming Machine:Power:1.5kw,Dimension:1320x950x1600mm,Weight:400kg

Jelly Filled Forming Machine:Power:2.2kw,Dimension:1200x1200x1300mm,Weight:650kg

Coating machine:Power:2kw,Dimension:1050x1050x1600mm,Weight:350kg

3.Automatic square chewing Gum Production Line

Automatic square chewing gum Production Line

Main Performance

Automatic Bubble Gum Production Line is an automatic production line integrates forming, cutting and packing for square chewing gum,square shapes of tablet chewing gum, rectangle chewing gum,circular chewing gum,filled chewing gum that. It takes the advantages of high production efficiency and low defect rate. It can produce all kinds of shapes and specifications products as customers* requirement. For example, chewing gum and square shapes of tablet, rectangle and circular with center Ailed, colors filled and so on.

Process flow chart of Automatic chewing gum Production Line

Automatic feeding/dust cleaning/crushing machine-mixer-extruder-cooling tunnel-block cutting pillow packing machine-low temperature double vacuum cooker-gum base oven

Main Technical Parameters For Production Line

Capacity:750-850(kg/h)

Power Supply:380V

Gross Power:143kw

Dimension:17300X5500X1800mm

Adjustable Range for Candy:18-80mm

Gross Weight:15000kg

Technical Parameters For Each Machine

Automatic feeding/Dust Cleaning/Crushing Machine:Main power:17kw,Dimensions:3500x1300x2200mm,Weight:400kg.

Mixer-100L:Main power:20kw,Dimensions:2300x860x1550mm,Weight:1500kg

Mixer-200L:Main power:24kw,Dimensions:2650x1000x1650mm ,Weight:2000kg

Extruder-One Color: Main power:15kw ,Dimensions:2500x900x1500mm ,Weight:1000kg

Extruder-Two Color:Main power: 22kw ,Dimensions:2600x1150x1500mm ,Weight: 2200kg

Jelly Pump:Main power:3kw,Dimensions:1600x550x1650mm,Weight:300kg

Cooling Tunnel-600:Main power:20kw,Dimensions:8850x1900x1850mm,Weight: 2500kg

Cooling Tunnel-800:Main power::22kw,Dimensions:8850x2100x1850mm ,Weight:2700kg

Block Cutting Pillow Packing Machine (Sets):Main power:4kw,Dimensions:2150x900x1500mm,Weight:980kg

Low Temperature Double Vacuum Cooker:Main power: 29kw,Dimensions: 3300x1600x3200mm ,Weight: 2500kg

Gum Base oven:Main power:18kw,Dimensions:1600x600x1700mm ,Weight: 300kg

4.Irregular shape Chewing Gum Production Line

Irregular shape Chewing Gum Production Line

Parameters

Capacity:150~300kg/h

100L Mixer:power:7.5kW,Dimensions:1900x660x1200mm, weight:1200kg

200L Mixer:power:18.5kW,Dimensions:2250x950x1550mm, weight:2000kg

Pressing machine:power:5.5kW, Dimensions:6200x1000x1500mm.weight:3000kg

The Irregular shape Chewing Gum Production Line main consists of mixer, extruder, forming machine, cooling machine and coating pan.

5.Automatic Xylitol chewing gum production line

Automatic Xylitol chewing gum production line

This fully-automatic xylitol chewing gum production line consists of mixer, extruder, six roller tablet, forming machine, cooling tunnel, automatic screening machine, gum base oven and coating machine. This machine features in reliable performance, simple and flexible operation, high automation. It is one of the good choices for producing xylitol chewing gum candy.

Process flow chart of xylitol chewing gum Production Line

mixer-extruder-six roller tablet-forming machine-cooling tunnel-automatic screening machine-gum base oven-coating machine

Main Technical Parameters For Production Line

Capacity:500-600(kg/h)

Adjustable range for candy:Bean Shape:6mm-22mm;Rectangle Shape:6mm-30mm,Circular shape:6mm-22mm

Dimension:22000x1800x1750 mm

Gross power:75 kw

Power supply:380V/50HZ 200V-240V/60HZ

Gross weight:11000 kg

Main component equipment

Extruder(single color)

The device is used to chewing Gum. The hopper is made of stainless steel, and the extruder head is made of high-hardness steel and coated with teflon. The extruder head is insulated by hot water circulation, which can ensure the temperature and softness of the rubber base, and ensure that it is easy to extrude without cracks.

Power:15kw

Dimensions:2500*900*1500mm

Machine weight:1000kg

Extruder(two color)

Power:22kw

Dimensions:2600*1150*1500mm

Machine weight:2200kg

Forming machine

Power:1.5kw

Dimensions:1320*950*1600mm

Machine weight:400kg

The forming machine produces chewing Gum in a variety of sizes according to customer requirements.

Coating machine

Power:2.2kw

Dimensions:1600*730*1450mm

Machine weight:350kg

This machine is used for polishing the candy surface.

Structure features:

The machine is composed of frame,worm gear box,icing pan,heating device,fan,electric appliance and other parts.lt is driven by an electric motor through a triangular belt to drive the worm wheel and then rotate the pan. Under the action of centrifugal force, the material is rolled up and down in the pan to achieve the effect of mixing, pelting and polishing.

Cooling Tunnel

Cooling Tunnel(600)

Power:20kw

Dimensions:8850*1900*1850mm

Machine weight:2500kg

Cooling Tunnel(800)

Power:22kw

Dimensions:8850*2100*1850mm

Machine weight:2700kg

Mixer

This machine is designed to mix chewing Gum raw materials and features a high efficiency.

Mixer(100)

Power:20kw

Dimensions:2300*860*1550mm

Machine weight:1500kg

Mixer(200)

Power:24kw

Dimensions:2650*1000*1650mm

Machine weight:2000kg

Gum base oven

Power:18kw

Dimensions:1600*600*1700mm

Machine weight:300kg

Jelly Filled Forming Machine

Power:2.2kw

Dimensions:1200*1200*1300mm

Machine weight:650kg

6.Chewing Gum types (candy shapes) and applications

Can make different shapes of chewing gum: ball chewing gum, square chewing gum, shaped chewing gum, sandwich chewing gum and so on

Chewing gum not only helps to freshen your breath, but also helps to remove food particles and bacteria from your teeth that are associated with bad breath. It does this by stimulating saliva, which is actually gargling. Chewing sugar-free gum for 20 minutes after meals can help prevent tooth decay, as the act of chewing sugar-free gum protects teeth by producing saliva to wash away bacteria.

Chewing gum after meals can replace brushing and flossing to prevent cavities and increase saliva production. Gum also stimulates saliva production naturally, so it can also help reduce saliva or dry mouth

7.Chewing gum chewability

The polymers that make up the bulk of gum - based sugars are hydrophobic. This property is crucial because it preserves the physical properties throughout the chewing process. Since gum polymers repel water, the water-based saliva system in the consumer's mouth dissolves the sugar and flavoring in the gum, but not the base. This allows the gum to be chewed for a long time without breaking down in the mouth like traditional food. Chewing gum can be classified as products containing liquid and crystalline phases, thus providing the characteristic balance of plasticity and elasticity for chewing gum.

8.Chewing Gum making Machine Working Principle

Chewing Gum production line consists of mixer, extruder, molding machine, cooling machine and icing machine. It is the production of various shapes of Chewing gum candy, such as ball, watermelon, oval, square, long piece shape and so on. The output of the equipment is beautiful in shape, stable in machine performance, simple in operation and maintenance.

The line can also produce a variety of single or two color Chewing gum. The Chewing gum production line has high efficiency, good sanitary conditions and stable operating performance.

First, the colloidal base is prepared in advance by melting and filtration or filtration processes. The formulations of gelatin-based sugar bases are proprietary information that few people in each gelatin-based sugar manufacturing company know. Next, other ingredients (such as nutritive and non-nutritive sweeteners and flavorings) are added to the gelatin-based sugar base until the warm mixture thickens like dough. The colloidal sugar base mixture is heated during this mixing process to increase the entropy of the polymer in order to achieve a more uniform dispersion of the components. Then, extruder implements techniques to smooth, shape and shape the gum. Next, the gum goes through a molding process determined by the type of gum and consumer needs. For example, use a vertical cutter to cut and wrap (block or cube) parts directly from the extruder. Laminating is a technique often used in viscose, thick sheet and sheet adhesives. Next, the glue is dusted with powdered polyols for conditioning, or is coated using a temperature-controlled coating basin by coating in subsequent layers before it is sent into packaging.

9.Installation of the Chewing gum making machines

We will send engineers to help you install the machine

10.Chewing gum production line for sales and price

You can leave us a message or contact us on whatsapp, and we will provide you with the best solution and quotation for your chewing gum processing machine according to your situation

Chewing gum production line video

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer