![]()

Adr :636 Yunqiao Road, Pudong New Area, Shanghai, China

Phone : +86 18221614363

Email : zhimachine@foxmail.com

Tel : +86 18221614363

processing capacity:20-3000kg/H

Application scope:Machine that makes chocolate candy, chocolate bars, chocolate bars, chocolate Snickers bars, and chocolate beans

Product introduction: Automatic chocolate production line includes depositing chocolate candy bar production die-formed chocolate candy making machine and extrusion chocolate bean making equipment,Machine that makes chocolate candy, chocolate bars, chocolate bars, chocolate Snickers bars, and chocolate beans

Automatic chocolate production line includes depositing chocolate candy bar production die-formed chocolate candy making machine and extrusion chocolate bean making equipment,Machine that makes chocolate candy, chocolate bars, chocolate bars, chocolate Snickers bars, and chocolate beans

1.Automatic Depositing Chocolate Production Line

Single-head Depositing Chocolate Production Line

Double-head Depositing Chocolate Production Line

Three-head Depositing Chocolate Production Line

2.Automatic chocolate candy production line

3.Automatic Chocolate Snickers production line

4.Chocolate bean production line

5.Automatic Chocolate energy stick high production line

6.Nut Chocolate candy depositing production line

7.Automatic Chocolate candy bar production line

8.Chocolate Moulding Line(Golden coin chocolate,Chocolate bar)

9.Chocolate candy types (Chocolate candy shapes) and applications

10.Chocolate making Machine Working Principle

11.Installation of the Chocolate making machines

12.Chocolate Candy production line for sales and price

1.Automatic Depositing Chocolate Production Line

Automatic single-head,double-head and three-head Chocolate depositing production line

Main function

Chocolate depositing and forming machine is an advanced machine used for producing chocolate products. The machine integrates the procedures of mold drying, depositing, vibrating, scraping, mold turning, cooling, molding and transporting together. It adopts PLC automatically control and used to produce pure chocolate, filled chocolate and double-color chocolate with colors at the upside, downside, left and right. The two heads or three heads can work separately

Model:Single-head Depositing Chocolate Production Line

Output per shift:1.5-3.0Tons/shift

:Depositing speed:8-15Moulds/min

Chocolate product weight-Pure chocolate:0-600g

Chocolate product weight-Central-filled chocolate:15-30%

Temperature in cooling tunnel:5-10°C

Working environment temperature:22-25°C

Cooling power:15HP water cooling and freezing unit

Cooling ways:It adopts centrifuge for closed and circulated cooling

Voltage:380V/50Hz

Total power:28kw

Mold size and quantity:300*225*30mm 220pieces needed

Gross weight(kg):8500kg

Outline dimensions(L*W*H):16000*1500*2000mm

Model:Double-head Depositing Chocolate Production Line

Output per shift:1.5-3.0Tons/shift

:Depositing speed:8-15Moulds/min

Chocolate product weight-Pure chocolate:0-600g

Chocolate product weight-Central-filled chocolate:15-30%

Temperature in cooling tunnel:5-10°C

Working environment temperature:22-25°C

Cooling power:15HP water cooling and freezing unit

Cooling ways:It adopts centrifuge for closed and circulated cooling

Voltage:380V/50Hz

Total power:32.5kw

Mold size and quantity:300*225*30mm 220pieces needed

Gross weight(kg):11500kg

Outline dimensions(L*W*H):19000*1100*1800mm

Model:Three-head Depositing Chocolate Production Line

Output per shift:1.5-3.0Tons/shift

:Depositing speed:8-15Moulds/min

Chocolate product weight-Pure chocolate:0-600g

Chocolate product weight-Central-filled chocolate:15-30%

Temperature in cooling tunnel:5-10°C

Working environment temperature:22-25°C

Cooling power:20HP water cooling and freezing unit

Cooling ways:It adopts centrifuge for closed and circulated cooling

Voltage:380V/50Hz

Total power:43kw

Mold size and quantity:300*225*30mm 360pieces needed

Gross weight(kg):15000kg

Outline dimensions(L*W*H):45000*1200*2200mm

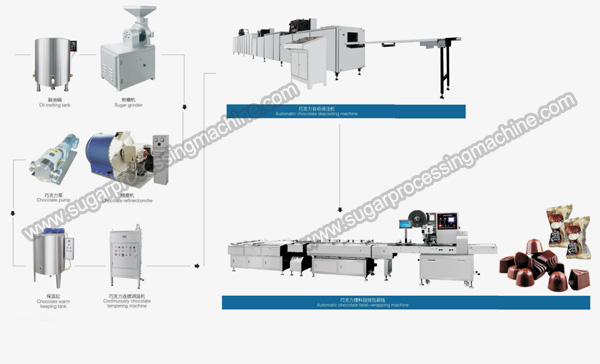

2.Automatic chocolate candy production line

Chocolate candy production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Automatic chocolate depositing machine-Automatic chocolate twist wrapping machine

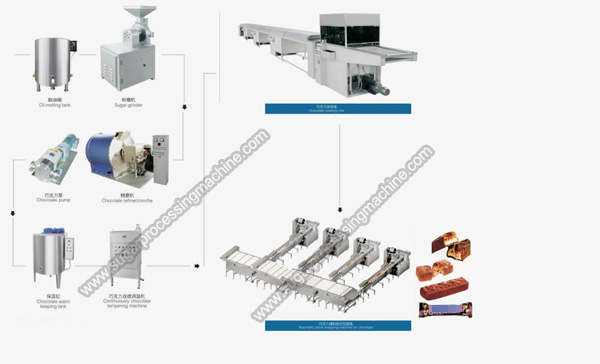

3.Automatic Chocolate Snickers production line

Automatic Chocolate Snickers production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Chocolate coating machine-Automatic pillow wrapping machine

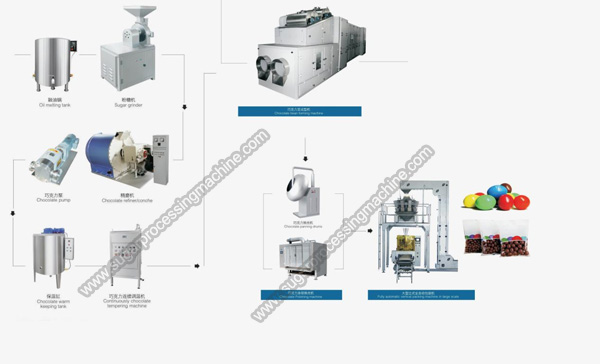

4.Chocolate bean production line

Automatic Chocolate bean production process flowchart

Oil melting tank-sugar grinder-Chocolate refiner-Chocolate pump-Chocolate warm keeping tank-Continuously chocolate tempering machine-Chocolate bean forming machine-Chocolate panning drums-Chocolate polishing machine-Automatic vertical packing machine

Main Performance

Chocolate bean with two kinds of different technology producing ways, one is powder chocolate forming, another is liquid chocolate forming. It is full set of chocolate production line which is composed , holding tank, crushing machine, vibration sieve, forming machine, chilling unit, screening machine etc. It is suitable for producing high quality chocolate in various kinds of shapes like round shaped, bean shaped and oval shaped etc.

Model:ZY-400

Belt width(mm):140

Belt speed(min):1-6

Supporting refrigeration unit:2

Tunnel length(m):10

Tunnel temperature(℃):2-10

Total Power(kw):10

Weight(kg):1800

Dimension(L*W*H)(mm):13160*700*1500

Model:ZY-600

Belt width(mm):600

Belt speed(min):1-6

Supporting refrigeration unit:3

Tunnel length(m):14

Tunnel temperature(℃):2-10

Total Power(kw):16.5

Weight(kg):2300

Dimension(L*W*H)(mm):18500*950*1800

Model:ZY-900

Belt width(mm):900

Belt speed(min):1-6

Supporting refrigeration unit:4

Tunnel length(m):18

Tunnel temperature(℃):2-10

Total Power(kw):22.87

Weight(kg):3200

Dimension(L*W*H)(mm):21500*1200*1800

Model:ZY-1200

Belt width(mm):1200

Belt speed(min):1-6

Supporting refrigeration unit:5

Tunnel length(m):22

Tunnel temperature(℃):2-10

Total Power(kw):28.5

Weight(kg):4050

Dimension(L*W*H)(mm):25500*1450*1800

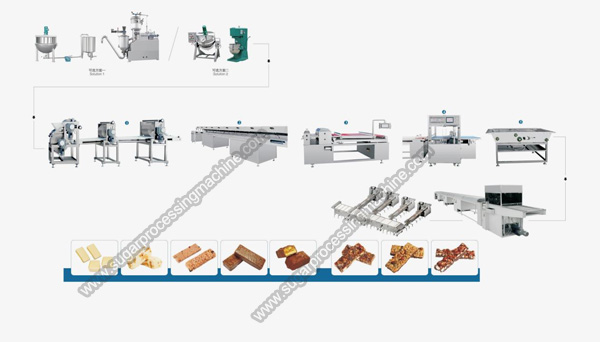

5.Automatic Chocolate energy stick high production line

Automatic Chocolate energy stick high production line

Technical parameters

-Production capacity: 400-600kg/h

-Candy bar length: 40-150mm

-Total power: 8.9kw

-Weight: 2880kg

-Dimension: 1390 x 1360 x 1400mm

Purpose and features

The machine is suitable for forming of mixed grains, red fruit sticks, fruit bars, nutritious sticks and other products that take sugar as the raw material and use it as the bond after boiling. This line consists of flattening machine (extruding machine as the option), cooling conveying cabinet (refrigerating equipment as the option), expanded cutting conveyor, finished product cutting machine and separating conveyor (three-phase variable frequency motor or servo motor as the option). It has such features as fast changing of cutting length of other specifications, human-machine operation interface and convenient maintenance.

6.Nut Chocolate candy depositing production line

Nut Chocolate candy depositing production line

Nut Chocolate candy continuously depositing production line is capable of making hard boiled Chocolate candy mixing with nut and dry fruit . this production line features spray nut or Chocolate automatically and support continuous depositing performance . this line has more advantages such as accurate spray location , less chip percentage , running automatically , easy to add nut Chocolate ingredient , fast dropping . nut Chocolate candy continuously depositing production line is perfect equipment to process nut and dry fruit mixing candy product .

Model:ZY-360

Capacity(5g candy):360kg/h

Power consumption(cooker):16kw

Power consumption(depositor):17kw

Compressed air consumption:0.5m3/min

Compressed air pressure:0.4-0.6Mpa

Steam consumption:450kg/h

Steam pressure:0.6-0.8Mpa

Water consumption:2200L/h

Size(L*W*H):13500*2000*2700mm

Weight:6000kg

Model:ZY-500

Capacity(5g candy):500kg/h

Power consumption(cooker):23kw

Power consumption(depositor):19kw

Compressed air consumption:0.5m3/min

Compressed air pressure:0.4-0.6Mpa

Steam consumption:500kg/h

Steam pressure:0.6-0.8Mpa

Water consumption:2200L/h

Size(L*W*H):13500*2500*2700mm

Weight:7500kgs

Model:ZY-720

Capacity(5g candy):720kg/h

Power consumption(cooker):23kw

Power consumption(depositor):23kw

Compressed air consumption:0.5m3/min

Compressed air pressure:0.4-0.6Mpa

Steam consumption:600kg/h

Steam pressure:0.6-0.8Mpa

Water consumption:2200L/h

Size(L*W*H):13500*2800*2700mm

Weight:8000kgs

7.Automatic Chocolate candy bar production line

Automatic Chocolate candy bar production line

Technical parameters

-Production capacity: 300kg/h

-Total power: 8.9kw

-Forming range: 40-100mm

-Weight: 2880kg

-Dimension: 12000*1360*1400

Purpose and features

The machine is suitable for forming of mixed grains, red fruit sticks, fruit bars, nutritious sticks and other products that take sugar as the raw material and use it as the bond after boiling. This line consists of expanded cutting conveyor, finished product cutting machine and separating conveyor (three-phase variable frequency motor or servo motor as the option). It has such features as fast changing of cutting length of other specifications, human-machine operation interface and convenient maintenance.

8.Chocolate Moulding Line(Golden coin chocolate,Chocolate bar)

Chocolate Moulding Line(Golden coin chocolate,Chocolate bar)

Main Performance

The chocolate moulding line is for chocolate deposit forming.The whole process is fully automatic including depositing, mould plate vibrating, cooling, demoulding, conveying and plate heating. You can choose one head, two heads or three heads moulding line for different products.The line is suitable for producing pure chocolate, center filled chocolate, two color chocolate, four color chocolate,etc.

Main Technical Parameters For Production Line

Power supply:380V/50HZ

Gross power:22kw

Capacity:300-500(kg/h )

Dimension:18000x1200x2200 mm

Mould size:470 x 200 x 30 mm

Mould quantity:280块(PCS)

Weight:6200kg

Main component equipment

Vacuum sugar cooking machine

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

①.Sugar melting cooker

Batch size(L):300

Weight(kg):280

Dimension(mm):1100*1100*1700

②.Storage tank

Batch size(L):300

Weight(kg):220

Dimension(mm):740*740*1250

③.Technical parameters

Production capacity(kg/h):350-400

Heating area(m³):2.45

Steam pressure(MPa):0.7-1.0

Steam consumption(kg/h):约about100

Syrup temperature before entering(°C):110-115

Temperature after discharging(°C):135-145

Power-Fixed displacement pump(kw):0.75

Power-Vacuum pump(kw):5.5

Dimension(mm):1900*1700*2300

Machine weight(kg):800

Continuous vacuum cooker

Main components: syrup pump, heater, syrup inlet, secondary steam discharge system, needle valve, vacuum steam chamber, discharge control system, rotary pot, vacuum system.

The jacketed cooking kettle is used to dissolve and cook ingredients such as glucose, granulated sugar, and water. It uses electric heating and features a large heating area, heating uniformity, and easy to control the temperature. This equipment improves product quality and shortens the processing time.

Working principle:

The purpose of boiling sugar is to remove most of the water in the sugar solution after melting sugar, so that the sugar paste eventually reaches a high concentration and retains less water. To turn the sugar solution into a thick sugar paste, this concentration must be increased by boiling evaporation process which increases the temperature gradient. This process is achieved through continuous boiling processing, so it is called boiling sugar. The water in the sugar solution needs to escape from the liquid level into the space and be eliminated. The faster the escape speed, the faster the boiling speed. Under the vacuum condition, the sugar liquid can be boiled and evaporated at a low temperature. The evaporation speed is fast and the product quality is good. Operating procedure: The process of vacuum boiling sugar is generally divided into preheating, evaporation and vacuum concentration three stages. The preheating stage is to increase the temperature and concentration of sugar solution and shorten the cycle of vacuum boiling sugar. During the evaporation stage, the remaining water in the sugar solution is removed.

Sugar boiling equipment is actually a set of evaporation and concentration equipment. The function of the heater is to have a proper heat source and a sufficient heat transfer area to heat the sugar liquid to boiling state. The evaporator can quickly remove water from the sugar liquid under boiling state, and the pump can stably transport the sugar liquid through the whole process to achieve continuous balanced production.

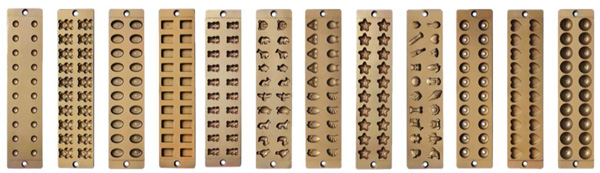

Mold

The production line manufactures candies in a variety of shapes using different molds. We will design molds according to your needs.

depositing die forming machine.

Casting die forming machine.

Main components: conveyor belt, model plate, sugar nozzle, sugar pump, storage tank, cooling device.

The machine is controlled by PLC system, temperature, casting speed and other parameters can be controlled on the touch screen. At the same time, frequency conversion speed regulation is used to control the accurate flow of sugar liquid, so that the quality of sugar paste is stable.

When the boiled sugar paste is still in the flow state during the casting mold molding, the liquid sugar paste is injected into the continuous running model plate, and then it is rapidly cooled and shaped, and then separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Working principle: The role of the sugar pouring pump is to push the sugar paste into the sugar filling mouth, which is made of two cylinders set, the outer cylinder is a fixed cylinder, there is a tank on the side and the storage tank through, and the hole at the bottom is connected with the sugar filling mouth. The inner cylinder is a opening and closing cylinder, and there is a connecting handle in the middle of the inner and outer circumference of the cylinder and a lever that swings from side to side. There is a small hole on the side and at the bottom of the cylinder. When swinging, the small hole at the bottom is closed with the small hole at the bottom of the outer cylinder, and the small hole on the side is connected with the hole of the storage tank, and the small hole on the bottom is connected with the hole on the side of the outer cylinder. There is a piston in the opening and closing cylinder, and when the piston moves up and down, the air can be inhaled, and the Jiang sugar paste is pressed to the sugar mouth. The piston moving distance determines the amount of sugar paste discharge. The piston moving distance can be adjusted according to the size of the sugar block. At the bottom of each pouring pump is a sugar nozzle, which equalizes the number of sugar models.

Chocolate coating machine

The machine is a special machine for producing various types of fancy chocolate products. It can coat chocolate paste on the surfaces of various kinds of food to form various chocolate products with unique tastes, such as wafer, biscuit,egg roll,cake and puffed food,etc.

9.Chocolate candy types (Chocolate candy shapes) and applications

10.Chocolate making Machine Working Principle

Chocolate molding: casting mold molding can be processed according to the mold of various shapes of chocolate, its wide range of adaptation, the need for equipment is roughly the same. When the boiling chocolate paste is still active, the liquid chocolate paste is injected into the continuous running model plate, and then it is rapidly cooled and shaped, and then separated from the model plate, and then sent to the packaging machine with the conveyor belt for packaging.

Extruded chocolate candy: This production line is composed of blender, extruded, forming machine, cooling conveyor cabinet, automatic grain separator, glue-based oven and coating machine into an automatic production line, can produce a variety of shapes of chocolate candy (such as square, rectangular, sheet shape, etc.). The machine has reliable production, flexible and simple operation, high degree of automation.

11.Installation of the Chocolate making machines

We will send engineers to help you install the machine

12.Chocolate Candy production line for sales and price

You can leave us a message or contact us on whatsapp, and we will provide you with the most suitable scheme and quotation for your chocolate processing machine according to your situation

All rights reserved:Zhi Yan Group Co., Ltd SitemapSitemapCandy making machine candy production line Toffee production line biscuit production line lollipop production line Gummy production line Popping boba production lineManufacturer